Recognizing the Functionality of Membrane Layer Switches Over for Interface Instruments

The performance of membrane changes represents a considerable improvement in interface layout, integrating performance with visual adaptability. These switches run with a multi-layered structure that translates customer communications into electric signals, enabling for both small designs and durability versus environmental factors. As sectors significantly focus on customer experience, understanding the subtleties of membrane layer switch innovation ends up being crucial. What ramifications do these improvements hold for future applications, and how might they redefine individual communications across various tools?

What Are Membrane Layer Buttons?

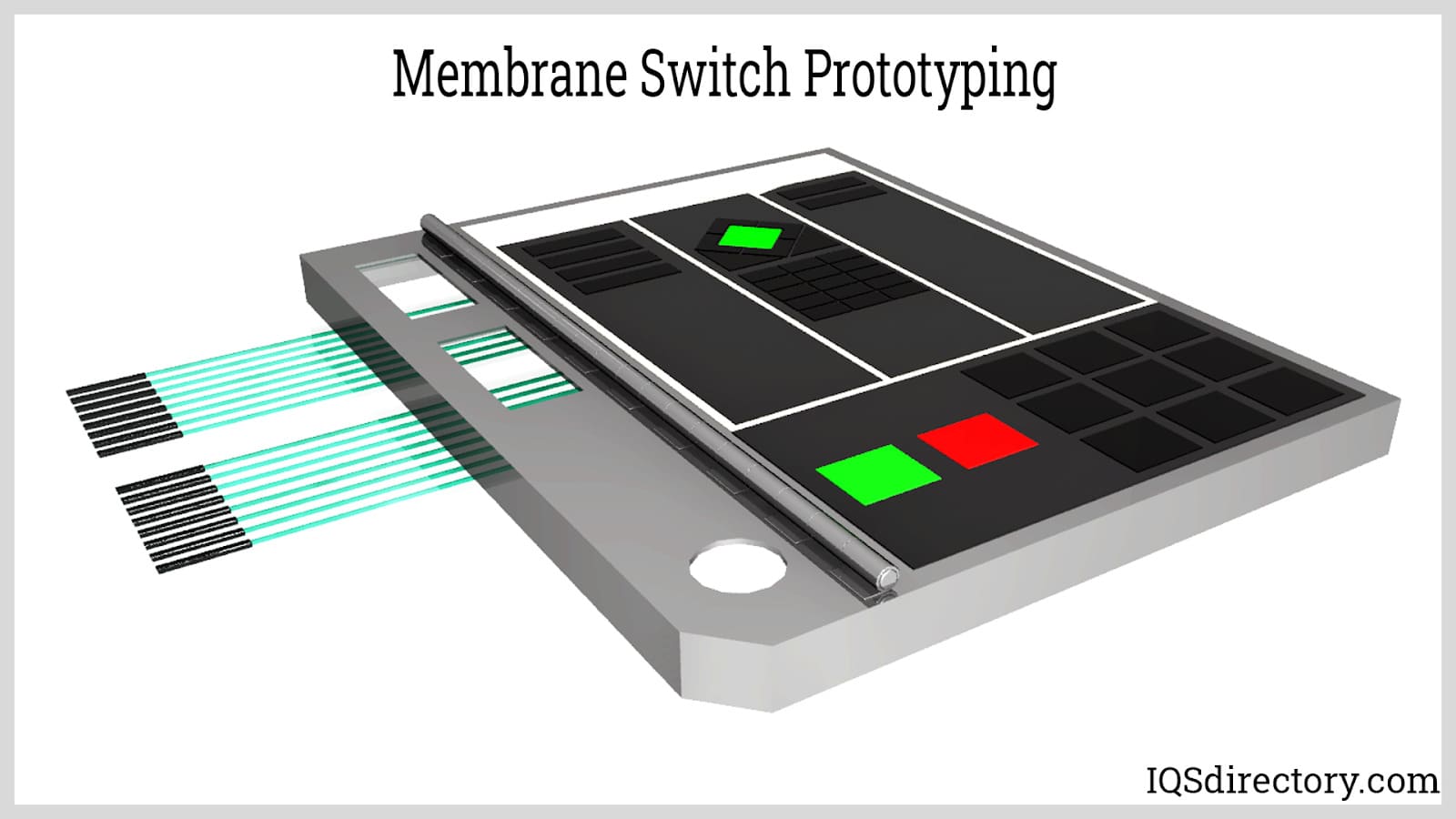

Membrane layer switches are innovative interface gadgets that help with user interaction with digital equipment. These functional elements consist of several layers, consisting of a graphic overlay, spacer, and a printed circuit layer. The style permits a smooth integration right into different electronic devices, enhancing both the visual and functional facets of user interfaces.

Membrane layer switches are frequently utilized in a variety of applications, from household home appliances to commercial equipment and medical gadgets. Their building typically includes a slim profile, making them a suitable choice for portable styles. The tactile feedback given by these switches can be engineered to fulfill certain customer preferences, guaranteeing effective communication between the individual and the device.

Resilience is an additional substantial advantage of membrane buttons, as they are immune to dirt, moisture, and chemicals, which improves their lifespan in demanding atmospheres. Additionally, these buttons can be customized in terms of form, dimension, and graphic design, enabling branding and user-specific attributes. Generally, membrane layer changes stand for a useful service for enhancing user experience in electronic devices, integrating capability with visual charm in an effective way.

Exactly How Membrane Layer Switches Over Work

Operating on a straightforward principle, membrane switches utilize a layered building and construction to sign up user input successfully. Each button includes several layers, including a printed circuit layer, a spacer layer, and a top visuals layer, which are developed to work together flawlessly. When a user presses the leading layer, it presses the spacer layer, bringing the conductive components of the circuit layer right into call with each other.

This call creates a closed circuit, signaling the tool to implement a certain function. The design permits for different setups, consisting of tactile responses, which can improve the individual experience by supplying a physical feeling upon activation. The products utilized in membrane switches frequently consist of versatile substrates, such as polyester or polycarbonate, which guarantee longevity and resilience against deterioration.

Trick Advantages of Membrane Buttons

An additional substantial advantage is their compactness. Membrane layer buttons are slim and Discover More light-weight, which makes it possible for manufacturers to conserve room in their gadgets without giving up capability. This attribute is specifically beneficial in applications where weight and volume are critical factors to consider.

Furthermore, membrane layer switches are resistant to dust, moisture, and chemicals, improving their toughness. This durability prolongs their lifespan and lowers the requirement for regular replacements, leading to expense financial savings gradually.

Furthermore, the responsive feedback given by membrane switches can be maximized to boost user communication. They can include features such as elevated switches or distinct clicks, boosting usability and user experience.

Applications Throughout Industries

Customer user interface tools using membrane layer switches prevail in a vast variety of markets, showcasing their adaptability and capability. Membrane Switch. In the read review clinical market, membrane switches are integral to tools such as analysis devices and patient monitoring systems, where their resilience and ease of cleansing are important for maintaining hygiene requirements. In the vehicle industry, these switches are used in dashboard controls and infotainment systems, offering a streamlined and contemporary user interface for customers.

Additionally, the customer electronic devices industry benefits from membrane layer buttons in devices and portable devices, where compact layout and user-friendly interfaces enhance individual experience. Industrial applications also utilize membrane layer switches over for control panels in equipment and automation systems, emphasizing their effectiveness and resistance to harsh environments.

In the aerospace and protection sectors, membrane switches are used in cabin controls and tools, where reliability and performance under severe conditions are extremely important. Furthermore, the gaming market increasingly incorporates membrane layer switches in controllers and arcade equipments, contributing to an engaging customer experience. In general, the adaptability of membrane changes allows their extensive use across numerous fields, underscoring their relevance in modern-day individual interface style.

Future Trends in Membrane Layer Change Modern Technology

In addition, the use of sophisticated products, such as polycarbonate and polyester films, is anticipated to rise, offering enhanced toughness and resistance to environmental stressors. These products add to the total durability of membrane layer buttons, making them ideal for harsher industrial applications.

In addition, the consolidation of smart modern technology, including IoT connectivity, will allow membrane layer switches to communicate with various other gadgets and systems, promoting a more interactive user experience. This pattern aligns with the growing demand for smart tools across various fields, from health care to customer electronic devices.

Lastly, personalization choices are expected to broaden, permitting makers to produce bespoke services tailored to details user needs and choices. These developments will place membrane buttons as important parts in the development of interface technology.

Final Thought

In conclusion, membrane switches over represent a critical improvement in customer interface technology, using a reliable and flexible option for diverse electronic applications. As improvements in product science and touch sensing technologies proceed, the capability and applicability of membrane buttons are expected to increase, reinforcing their importance in contemporary electronic devices.